Do you know the difference between a homogenizer and a DC blender?

Do you know the difference between a homogenizer and a DC blender?

Homogenizers and blenders are some of the most widely used laboratory benchtop equipment. While they look similar, they are different and

there are some considerations to take into account when choosing one over the other. Learn how to select based on your needs and sample type.

Stirring and mixing are basic procedures in the laboratory. These operations enable laboratories to achieve different goals: from the manufacture of final products to the preparation of samples for further analysis.

The market offers many options for this, which often look similar but can be very different, such as homogenizers and DC mixers.

Do you know how they differ and how to choose? We hope to provide you with some help in differentiating between the two options and recommending which one to use based on your needs and sample type.

The first important consideration is the sample type and solubility of the ingredients.

Flow-through agitators are typically used in applications where one or more soluble components are agitated and mixed.

If your goal is to mix two or more insoluble media, you will need a homogenizer to break up the particles and form a stable mixture.

In addition to mixing, homogenizers can also be used to emulsify, suspend, grind, disperse and dissolve a variety of samples.

Besides this significant difference, other essential characteristics to consider that differentiate the two instruments include:

1. Viscosity

Rotor/stator homogenizers are optimized to work best with samples that have low viscosities.

DC stirrers are able to accept very viscous samples and are suitable for applications where the sample increases in viscosity during the stirring process.

2. Capacity

Rotor-stator homogenizers can process relatively small volumes of fluid (up to about 2.5 liters).

DC mixers are suitable for very large capacities, up to 100 litres.

3. Speed

Homogenizers operate at very high minimum and maximum speeds (3,000 to 25,000 rpm for the new OV 625 Digital). In these applications, top speed is very important as it significantly reduces processing time and prevents sample damage due to heating.

The DC agitator also operates at very low speeds, with the top speed still lower than that of a homogenizer.

Discover VELP products: reliability, safety and performance in every procedure

VELP offers a wide range of solutions to support these procedures in the laboratory.

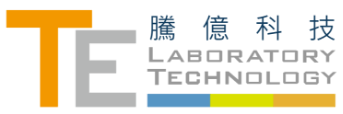

1. Homogenizer

If your requirements are to disperse, homogenize, emulsify or suspend two or more immiscible phases, the new OV 625 Digital offers high shear and superior performance with unrivalled precision, safety and practicality.

Learn more about the new OV 625 Digital >>

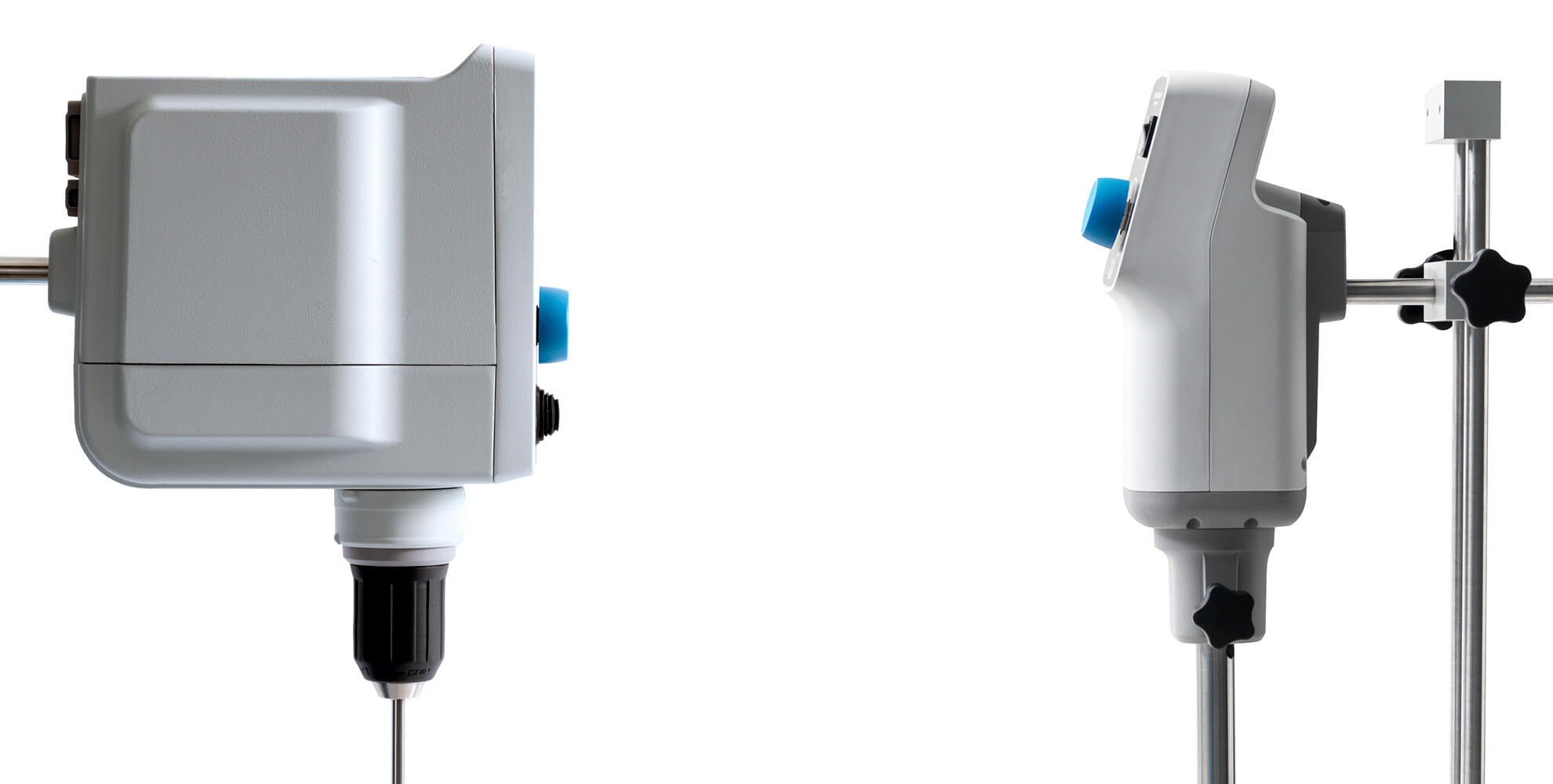

2. DC Stirrers

If you need to stir, mix one or more soluble samples, the OHS series offers state-of-the-art performance and high resistance in continuous operation even in the most demanding procedures.

The OHS series is powered by a high performance brushless motor, ensuring long service life and excellent reliability. Furthermore, VELP technology guarantees consistency regardless of speed and viscosity variations.

No matter what challenges you face, you can rely on Tengyi Technology's precise, reliable and powerful products

and entrust our Tengyi Technology team to find the best solution for your needs.

For original text, please visit: https://www.velp.com/en-ww/do-you-know-the-difference-between-a-disperser-and-an-overhead-stirrer.aspx

For product information, please visit: https://www.te-lab-equipment.com.tw/ov-625-digital-homogenizer.html

https://www.te-lab-equipment.com.tw/dc-stirrers.htm