Stirrer

We provide professional laboratory stirrers, heating stirrers, silent stirrers, magnetic stirrers, DC stirrers, DC stirrers, laboratory consumables, etc., various instruments and consumables.

Experts in laboratory mixers - TELAB

We provide professional laboratory stirrers, heating stirrers, silent stirrers, magnetic stirrers, DC stirrers, DC stirrers, laboratory consumables, etc., various instruments and consumables. The team of more than 20 years in the industry has provided you with a variety of product choices and perfect services, and is a professional laboratory equipment supplier. Instrument, physical and chemical, laboratory consumables service line: (02) 2874-4741

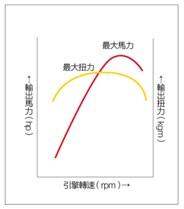

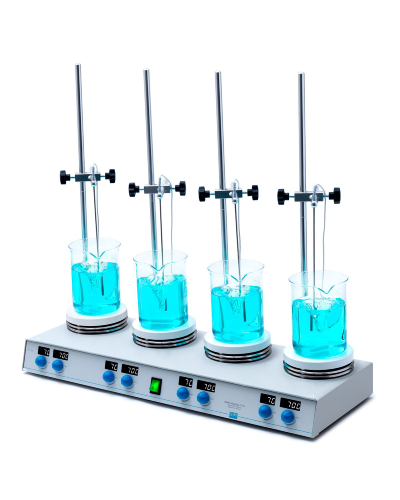

VELP multi-point electromagnetic stirrer, the stirring position can be stirred at 6 points and 15 points at the same time. The stirring volume can reach 400ml & 250ml (H2O). The only product in its class has torque compensation, reverse stirring, intermittent switch and timing functions.

VELP Electromagnetic Stirrer - TELAB Laboratory Electromagnetic Stirrer has the highest specification and 2-year warranty

VELP small electromagnetic stirrer, stirring volume up to 5L (H2O). The only product in its class with torque compensation, reverse stirring and timing functions. Model: MST/ MST Digital.

VELP high-torque electromagnetic stirrer, the stirring volume can reach 50L (H2O). The magnetic stirrer for vaccine research and development and production is the only one in its class with torque compensation, reverse stirring, intermittent switch and timing functions. Model: MSL8/ MSL25/ MSL50 Digital--stirring volume: 8L/25L/50L

VELP multi-point electromagnetic stirrer, the stirring position can be stirred at 6 points and 15 points at the same time. The stirring volume can reach 400ml & 250ml (H2O). The only product in its class has torque compensation, reverse stirring, intermittent switch and timing functions.

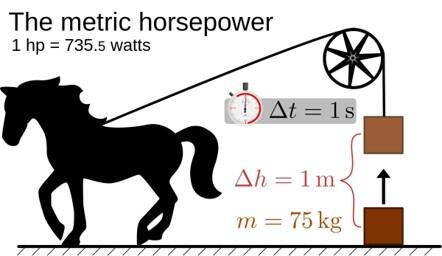

VELP Electromagnetic Stirrer - Stirrer Principle

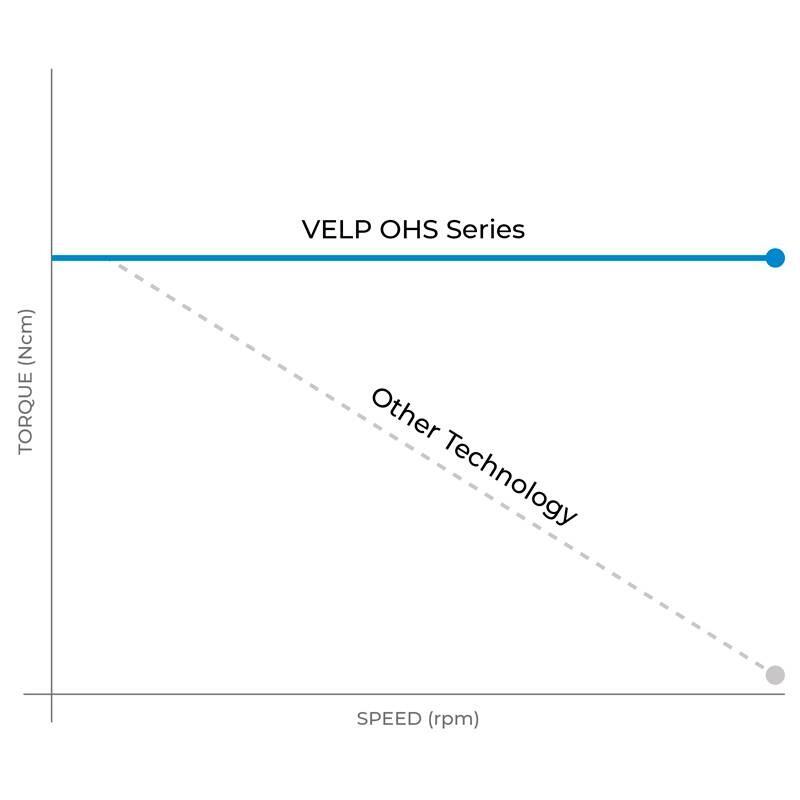

Horsepower = torque multiplied by speed

The stronger the torque, the weaker the speed

Torque speed is always inversely proportional

VELP Electromagnetic Stirrer - Stirrer Principle

- Stirring bar (composition mostly: Teflon+magnet)

The heating stirrer (magnetic stirrer) manufactured by VELP in Italy is the only electromagnetic heating stirrer in the world with a double-digit ceramic panel and a magnetic rod that can reverse forward and reverse.

The heating stirrer (magnetic stirrer) made by authentic Italian VELP is the only electromagnetic heating stirrer in the world with a double-digit ceramic panel and a magnetic rod that can rotate forward and reverse.

It has a high waterproof coefficient of IP42, acid and alkali resistance, corrosion resistance, temperature control, timing setting and the only patented wireless wired control function ERMES. The independent safety circuit ensures that the instrument can be protected in case of overheating to prevent accidental heating through buttons instead of knobs.

Heated mixer countertop heat warning system: Prevents potential burns, adjustable temperature limits. Probe alarm detects that the probe is not immersed in the medium and interrupts heat. Resistant die-cast housing (IP 42) for maximum protection of internal instrument components. Fast-heating CerAlTop™ plate resists chemicals and scratches to ensure long-term use. life, the mixing speed slowly increases to avoid the risk of spillage, and a silicone protective sleeve can be prepared to protect the mixer from oil spill damage.

Designed for maximum service life and backed by a 2-year warranty, the VELP Heated Blender AREX-6 Digital & PRO is engineered for performance and usability.

PID software controls the temperature adjustment to achieve fast, accurate and stable temperature control. The maximum temperature control accuracy of the heating stirrer can reach 370°C, and the precise temperature setting has a resolution of 1°C.

The powerful brushless engine is capable of revving from 30 RPM to 1700 RPM (5 RPM per stage) and can carry up to 20 liter flasks. Torque compensation technology SpeedServo™ helps keep the rotational speed constant under viscosity changes. Alnicon magnets provide the most advanced The latest magnetic coupling technology ensures easy and uniform stirring around the environment.

It has a timer for unattended operation and automatic reverse selection of the stirring direction to make the sample temperature more uniform and the mixing more uniform.

MultiAluBlock™ and new MonoAluBlock™ allow many reactions to be performed, saving time and bench space, new heating pack settings allow oil baths and masks to be changed for clean and safe reactions with round bottom flasks, PTFE safety lids are designed for To minimize heat dissipation and increase safety, Tengyi Technology provides you with the most suitable heating mixer and laboratory equipment solutions.

AREX-6 Digital (round panel) heated stirrer with PT100: Contains PT100 temperature probe, support rod and clamp, temperature control accuracy is 1°C.

AREX-6 Digital PRO with VTF Digital Temperature Regulator: Contains VTF and allows connection of a PT100 (titanium or glass) probe, with temperature control accuracy of 0.5°C.

NEW AREC.

NEW AREC 7 Connect (square panel) heating mixer: dual-screen display/speed 1700RPM/temperature 550°C/stirring volume 20L/reverse/intermittent operation/timing/Ermes cloud control and other functions.

Laboratory heating mixer with the highest specifications in the same class is the general agent in Taiwan - Tengyi Technology 1 Laboratory heating mixer with the highest specification in the same class is the general agent in Taiwan - Tengyi Technology 2

Laboratory heating mixer with the highest specifications in its class is the general agent in Taiwan - Tengyi Technology 3 Laboratory heating mixer with the highest specification in the same class is the general agent in Taiwan - Tengyi Technology 4

The VELP DC mixer OHS 200 Advance is VELP's highest specification mixer and is designed to ensure the highest safety standards. The robust sealed housing and IP 54 protection rating ensure durability even in the harshest environments. Integrated safety alarms for overload, overheating and overcurrent will maintain performance in the long term by stopping stirring, safe start and stop knob operation and locking keys avoid accidental starts and changes in working conditions, the OHS 200 DC stirrer has different sensitivity levels integrated The vibration sensor will stop operation and notify you. Make sure the OHS is stable and properly secured, the OHS 200 Advance ensures continuous operation and comes with a 2-year warranty.

The best-in-class stirring power of VELP OHS 200 Advance is the ideal solution for demanding applications with viscosity requirements up to 100.000 mPas. The electronically controlled brushless motor of the OHS 200 Advance DC mixer can stir up to 200 liters (maximum torque of 200 Ncm) and ensures the longest service life, and SpeedServo TM torque compensation technology automatically adjusts the speed according to viscosity changes to keep it constant , it provides optimal performance in both high-torque and high-flow operations thanks to two variable speed gears: Variable Gear 1: 6-400 rpm, Variable Gear 2: 30-2000 rpm, constant rotation at any speed Torque, brushless motor and microprocessor ensure outstanding performance that marks the difference between conventional blenders and the VELP VELP OHS series. Torque remains stable throughout the entire speed range, ensuring even at the highest speeds. Stirring at maximum torque is a very important parameter for test repeatability. A dedicated section of the screen provides precise torque measurement so you can monitor changes in torque power in real time during the test.

Smart Chuck: Shaft adjustment has never been easier! OHS Advance SmartChuck™ technology simplifies the shafting process, which can even be done with one hand and requires no tools, making your life easier. With two simple operations, you can unlock the protective ring for maximum protection. Easily drive the shaft in and out, opening the ring during mixing automatically blocks analysis and the instrument informs you for maximum safety.

The intuitive and precise 3.5-inch TFT display of the OHS 200 Advance DC stirrer will guide you to set working conditions precisely and achieve repeatable results. It shows main information at a glance as well as torque measurements on the display, which shows information on viscosity changes in real time. , with a resolution of 1 Ncm, interacts with OHS Advance via real-time graphs showing the speed, torque and temperature of the test.

The OHS 200 Advance DC Blender can be set on a timer from 1 minute to 99.59 hours so it can be left unattended. Define and program your operating methods, ideal for demanding tasks requiring ramp and interval operations. The OHS Advance DC stirrer controls the temperature and comes with a Pt100 temperature probe included in the package, which continuously monitors the reaction temperature and sets the instrument to reduce the speed or interrupt the task when the temperature reaches a defined value, when you want to avoid exothermic reactions that can disturb you This is important when analyzing!

The OHS Advance DC Mixer Advanced Connectivity is the only overhead mixer that can control and monitor the process via Wi-Fi connection to VELP Ermes and via USB.

VELP DC Mixer Ermes Cloud Platform allows controlling the OHS Advance from PC, smartphones and tablets via a simple and intuitive web interface. Using the VELP-designed platform, it is possible to activate stirring, set timers, set methods (including those saved in the device), download and share reports with a single click.

For applications in the pharmaceutical, biotech and life science sectors, VELP Ermes can manage OHS Advance DC mixers in clean rooms or other controlled environments without the need for lengthy safety procedures. With OHS/CotrollerSoft TM software, VELP provides a complete solution for all applications that cannot. Labs offer the possibility to benefit from cloud services, which are an effective alternative to USB connections.

FC4S & FC6S

Through the results of the Jar experiment, a standard for the selection and dosage of chemical reagents for removing suspended solids from sewage was established. VELP's multiple stirrers with multiple stirring speeds ensure reliable experimental results.

Removal of Colloidal Particles from Water Jar Test

In tap water treatment, there is a procedure called medicated coagulation. As the name suggests, chemicals need to be added into our treated water, but what are the functions of these added chemicals?

In the experiment of coagulation dosing, we will first prepare the same volume of water in a beaker, and then add it to the water at the same time according to different dosages. Then use a stirrer to quickly mix the coagulant and water, and then let it sit for a period of time. We You can clearly observe the generation of particulate matter from outside the cup, which accumulates at the bottom of the cup and bottle as time goes by. Finally, by analyzing the water in the upper layer, you can find the cleanest test water. This experiment is also a common "cup and bottle" experiment in water treatment. Jar test.

After this series of addition tests, the optimal addition amount can be known. This will not only effectively remove invisible colloidal particles from the water, but also reduce excess additives and be used in the purification unit of the water plant. . In addition, we will fine-tune the amount of medicine added depending on the turbidity of the monitored source water. This also shows that small experiments (cup and bottle tests) are still needed to find the most suitable conditions for different water quality conditions.